Pressure Relief Valve

Farris Pressure Relief

Safety Valve

2600 Series & 2600L Series – Process Valve

Farris’s pressure relief valves are designed to automatically protect your equipment against excessive overpressure. The Series 2600 pressure relief valves are designed to function equally well on air, gases, steam, or liquid service.

Features

- Conforms to API 526

- Full Nozzle Design

- Integral Cast Flanges

- Metal Seat with optional o-ring

- Balanced Bellows option

- Open Bonnet and Lever Assemblies option

Detail Specification

| Size | 1” x 2” to 20” x 24” |

| Set pressure Ranges | 15 to 6000 psig (1.0 to 413 barg) |

| Temperature Ranges | -320 to 1500°F (-195 to 815°C) |

| Flanges Classes | 150# – 2500# |

| Suitable For | Air, Gas, Vapor, Steam & Liquid Service |

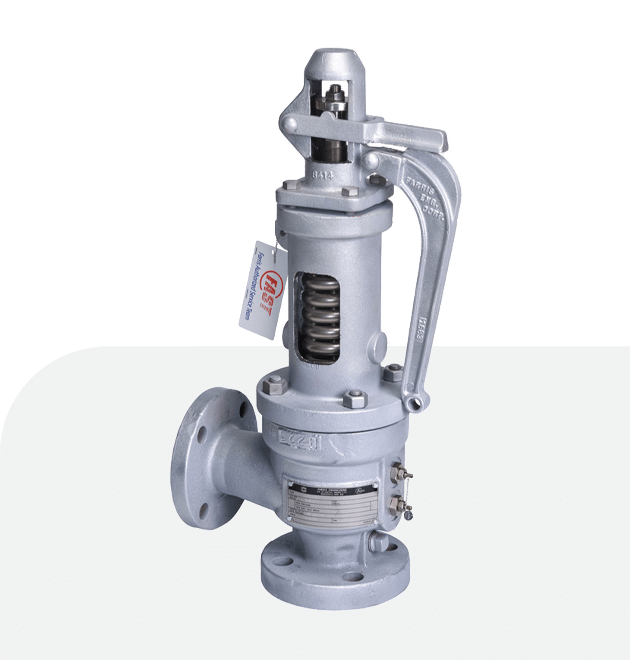

Farris Pressure Relief

Safety Valve

2400 Series – Pressure

Relief Valve

A high performance direct spring loaded pressure relief valve with a soft seat design to provide reliable overpressure protection.

Features

- ASME Section VIII

- Direct Spring Loaded

- Soft Seat Design

- External Blowdown Control

- Full Lift at Set Pressure

Farris Other Series

- Farris Smart PRV

- Farris 1890 Series – Process Valve

Detail Specification

| Size | Cast steel, ASTM A216, GR. WCB |

| Orifice Areas | B (0.049 in2) to E (0.196 in2) |

| Set Pressure Ranges | 20 to 2,000 psig (1.38 to 137.9 barg) |

| Seat Materials | Elastomer, Plastic |

| Suitable For | Air, Gas, Vapor |

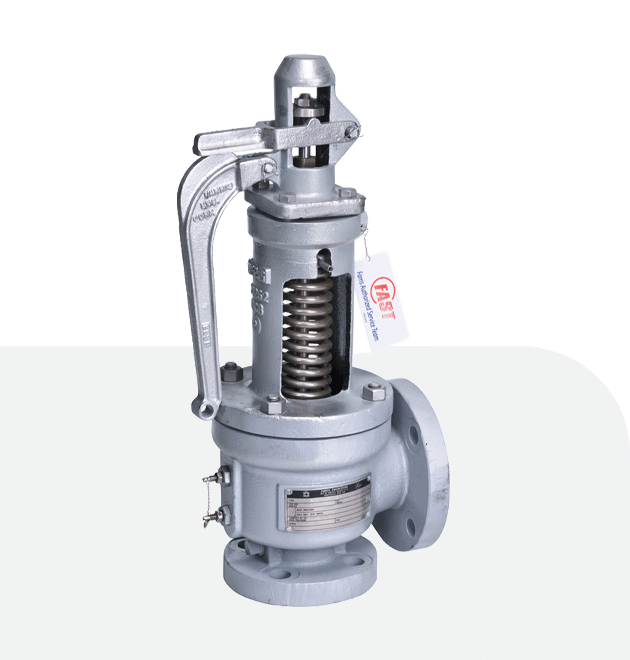

Farris Pressure Relief

Safety Valve

2400 Series – Pressure

Relief Valve

A high performance direct spring loaded pressure relief valve with a soft seat design to provide reliable overpressure protection.

Features

- ASME Section VIII

- Direct Spring Loaded

- Soft Seat Design

- External Blowdown Control

- Full Lift at Set Pressure

Farris Other Series

- Farris Smart PRV

- Farris 1890 Series – Process Valve

Detail Specification

| Size | Cast steel, ASTM A216, GR. WCB |

| Orifice Areas | B (0.049 in2) to E (0.196 in2) |

| Set Pressure Ranges | 20 to 2,000 psig (1.38 to 137.9 barg) |

| Seat Materials | Elastomer, Plastic |

| Suitable For | Air, Gas, Vapor |

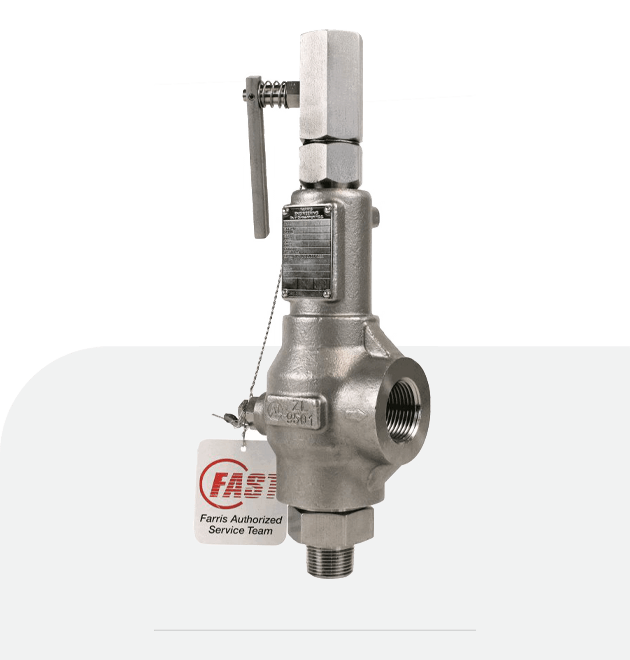

Farris Pressure Relief

Safety Valve

2700 Series – Process Valve – Pressure Relief Valve

The 2700 Series pressure relief valve, also known as an expansion relief valve, features a superior design that handles air, steam, vapor, and liquid services.

Features & Benefits

- Metal Seat with optional o-ring

- Balanced design option

- Flanged option

Materials of Construction

- Carbon Steel

- Stainless Steel

- Low/High Temperature Alloy Steels

Detail Specification

| Size | 1/2” x 1” to 1-1/2” x 2-1/2” |

| Set pressure ranges | 15 to 6500 psig (1.0 to 413 barg) |

| Temperature ranges | -320 to 750°F (-195 to 399°C) |

| Flange classes | 150# – 2500# |

| Suitable for | Air, Gas, Vapor, Steam & Liquid Service |

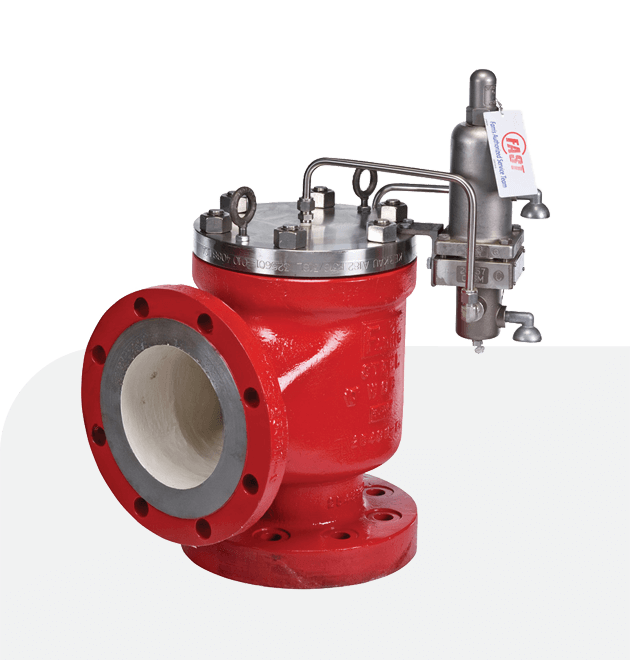

Farris Pressure Relief

Safety Valve

3800 Series – Process Valve

Farris’ 3800 Series valves feature an innovative, integrally cast, flanged body with a semi-nozzle design. Series 3800 valves are self-contained units actuated by either the snap-acting or modulating style pilot controls.

Features

- Snap Acting and Modulating Control Actuation

- Semi and Full Port Nozzle Design

- Typical Blowdown of 3-6%

Farris Other Series

- 1896 Series – Steam Safety Valve

- 4700 Series – Steam Safety Valve

Detail Specification

| Size | 1” x 2” to 12” x 16” |

| Set Pressure Ranges | 15 to 6170 psig (1.0 to 425 barg) |

| Temperature ranges | -320 to 500°F (-195 to 260°C) |

| Flange Classes | 150# – 2500# |

| Suitable For | Air, Gas, Vapor, Steam & Liquid Service |

Farris Pressure Relief

Safety Valve

3800 Series – Process Valve

Farris’ 3800 Series valves feature an innovative, integrally cast, flanged body with a semi-nozzle design. Series 3800 valves are self-contained units actuated by either the snap-acting or modulating style pilot controls.

Features

- Snap Acting and Modulating Control Actuation

- Semi and Full Port Nozzle Design

- Typical Blowdown of 3-6%

Farris Other Series

- 1896 Series – Steam Safety Valve

- 4700 Series – Steam Safety Valve

Detail Specification

| Size | 1” x 2” to 12” x 16” |

| Set Pressure Ranges | 15 to 6170 psig (1.0 to 425 barg) |

| Temperature ranges | -320 to 500°F (-195 to 260°C) |

| Flange Classes | 150# – 2500# |

| Suitable For | Air, Gas, Vapor, Steam & Liquid Service |

Farris Pressure Relief

Safety Valve

4200 Series – Steam

Safety Valve

The 4200 Series was designed to meet your requirements for a dependable, cost effective, high capacity boiler safety valve. This product is manufactured in our Brecksville, Ohio, ISO 9001 certified facility.

Features

- Flanged Spring Loaded Boiler Safety Valve

- Full nozzle design

- Open bonnet design

- One piece guide

- Low stem bearing point

- Temperature equalizing disc

- Heavy stainless steel lock screw studs

Detail Specification

| Size | 1” x 1/4” x 1-1/2” to 6” x 8” |

| Orifice Areas | F (0.316 sq2) to Q Orifice (11.39 sq2) |

| Set Pressure Ranges | 15 to 1000 psig (1.0 to 68.9 barg) |

| Temperature Ranges | -20 to 1000°F (538°C) |

| Body Material | 316 Stainless Steel, ASTM A576 Carbon Steel |

| Flange Classes | 150# – 600# |

Farris Pressure Relief

Safety Valve

6400 Series – Steam

Safety Valve

Series 6400 and 6600 safety valves represent the most advanced technology in valves designed for use in intermediate power boiler and organic fluid vaporizer service.

Features

- Hardened conical disc for extended seat life

- Full nozzle design

Materials of Construction

- Carbon Steel

- Stainless Steel

- Chrome-Moly

Detail Specification

| Size | 1” x 2” to 4” x 6” |

| Orifice Areas | D (0.150 sq2) to P Orifice (7.087 sq2) |

| Set Pressure Ranges | 15 to 1500 psig (1.0 to 103barg) |

| Temperature Ranges | -20 to 1000°F (-29 to 538°C) |

| Flange Classes | 150# – 1500# |

| Materials of Construction | Carbon Steel, Stainless Steel, Chrome-Moly |

Farris Pressure Relief

Safety Valve

6400 Series – Steam

Safety Valve

Series 6400 and 6600 safety valves represent the most advanced technology in valves designed for use in intermediate power boiler and organic fluid vaporizer service.

Features

- Hardened conical disc for extended seat life

- Full nozzle design

Materials of Construction

- Carbon Steel

- Stainless Steel

- Chrome-Moly

Detail Specification

| Size | 1” x 2” to 4” x 6” |

| Orifice Areas | D (0.150 sq2) to P Orifice (7.087 sq2) |

| Set Pressure Ranges | 15 to 1500 psig (1.0 to 103barg) |

| Temperature Ranges | -20 to 1000°F (-29 to 538°C) |

| Flange Classes | 150# – 1500# |

| Materials of Construction | Carbon Steel, Stainless Steel, Chrome-Moly |