Pressure Relief Valve

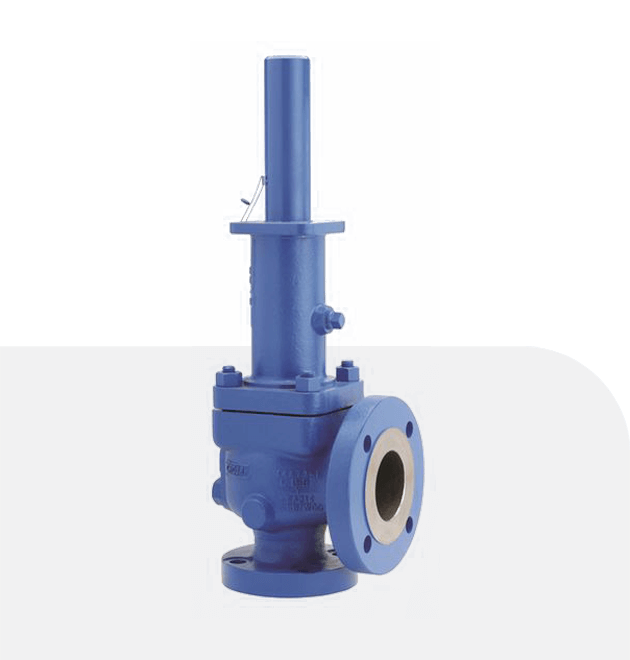

Crosby Pressure Relief Valve

Crosby J-Series Direct Spring Pressure Relief Valve

J-Series valves provide high quality and dependable overpressure protection for air, gas, steam, vapor, liquid and two-phase applications in one simple design

Features

- API 526 valve with EN 1092-1 inlet and outlet connections

- ASME VIII/NB certified capacities for gas, liquid and steam

- PED 2014/68/EU certified

- Interchangeable parts to reduce maintenance costs

- Full nozzle configuration

- Simple and reliable design

Detail Specification

| Sizes | DN 25 x 50 to DN 200 x 250 |

| Orifices | 71 to 16,774 mm² (D to T orifice sizes) |

| Ratings | PN 10 to 40 |

| Temperature range | -268 to 538°C / -450 to 1000°F |

| Pressure range | 0.35 to 40 barg / 5 to 580 psig |

Crosby Pressure Relief Valve

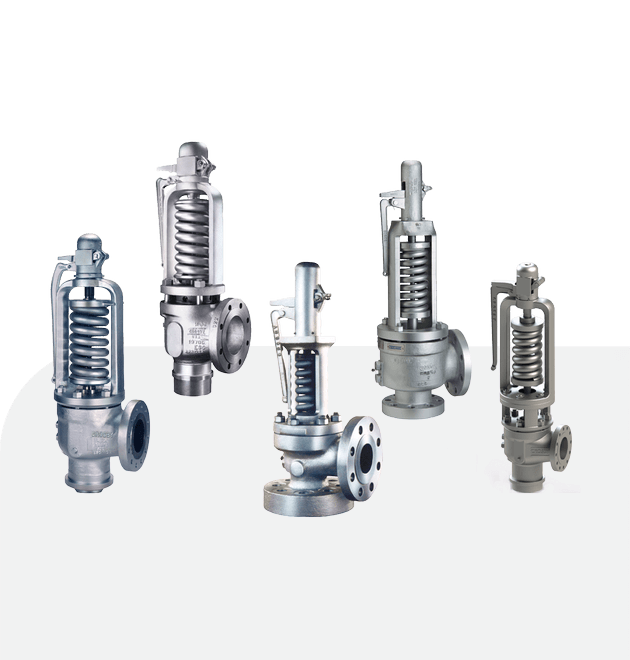

Crosby H Series Direct Spring Safety Valve

Direct spring safety valves that provide comprehensive overpressure protection for ASME Boiler and Pressure Vessel Code Section I, and Section VIII steam safety applications

Features

- Extends Up-time

- Reduces Maintenance Costs

- Easily Adjustable for ASME Boiler and

Product Overview

The HE ISOFLEX incorporates our latest field proven seat tightness design which allows boilers to operate close to set pressure without leakage across the valve seat.

Detail Specification

| Material | 316 Stainless Steel, Aluminum Bronze, Buna-N, Cast Iron, Ductile Iron, Epdm Rubber, Teflon |

| Operating Temperature | Up to 350 F (180 C) |

| Process Connection Type | 150RF |

| Standards | API 609, ASME B16.34 |

| Valve Size | 5 inch, NPS 10 / DN 250, NPS 12 / DN 300, NPS 14 / DN 350, NPS 16 / DN 400, NPS 18 / DN 450, NPS 20 / DN 500, NPS 2-1/2 / DN 65, NPS 3 / DN 80, NPS 4 / DN 100, NPS 6 / DN 150, NPS 8 / DN 200 |

Crosby Pressure Relief Valve

Crosby H Series Direct Spring Safety Valve

Direct spring safety valves that provide comprehensive overpressure protection for ASME Boiler and Pressure Vessel Code Section I, and Section VIII steam safety applications

Features

- Extends Up-time

- Reduces Maintenance Costs

- Easily Adjustable for ASME Boiler and

Product Overview

The HE ISOFLEX incorporates our latest field proven seat tightness design which allows boilers to operate close to set pressure without leakage across the valve seat.

Detail Specification

| Material | 316 Stainless Steel, Aluminum Bronze, Buna-N, Cast Iron, Ductile Iron, Epdm Rubber, Teflon |

| Operating Temperature | Up to 350 F (180 C) |

| Process Connection Type | 150RF |

| Standards | API 609, ASME B16.34 |

| Valve Size | 5 inch, NPS 10 / DN 250, NPS 12 / DN 300, NPS 14 / DN 350, NPS 16 / DN 400, NPS 18 / DN 450, NPS 20 / DN 500, NPS 2-1/2 / DN 65, NPS 3 / DN 80, NPS 4 / DN 100, NPS 6 / DN 150, NPS 8 / DN 200 |

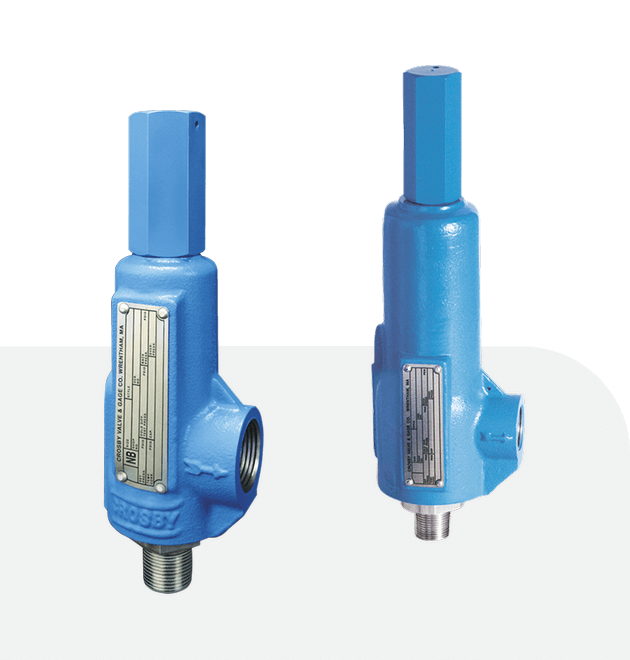

Crosby Pressure Relief Valves

Crosby OMNITRIM Pressure Relief Valve

Reliable and economical overpressure protection for thermal relief and many more applications

Features

- Full nozzle configuration

- Simple and reliable design

- Soft seat options for superior seat tightness

- BP balanced piston option to offset the effects of variable back pressure

Product Overview

Series 900 OMNI-TRIM pressure relief valves provide overpressure protection on air, gas, vapor, liquid thermal relief and steam service.

Detail Specification

| Sizes | ½” x 1" to 2" x 2" and 1½” x 2½” |

| Orifices | 0.074 to 0.503 in2 (47.74 to 324.5 mm2 ) |

| Connections | NPT, flanged, male socket weld |

| Temperature range | 450 to +750°F (-268 to +399°C) |

| Set pressures | 5 to 5000 psig (0.34 to 344.83 barg) |

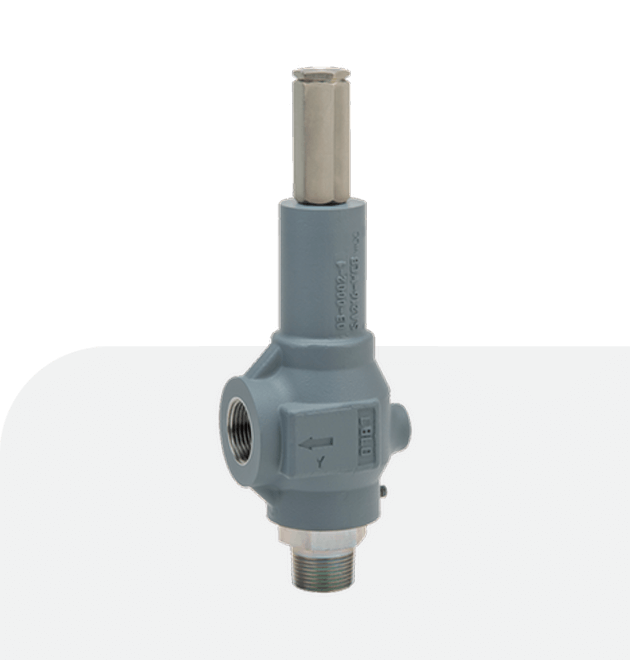

Crosby Pressure Relief Valve

Crosby Series 82 Direct Spring Operated PRV for Natural Gas

High performance, direct spring operated pressure relief valve for natural gas applications

Features

- Two piece body design with easily replaceable seat and seals reduces downtime and maintenance costs

- FKM soft seat provides repeatable leak-tight performance before and after each relief cycle

- Bubble tight at 90%

- Manufactured to ASME Section VIII UV for gas service

- Gas service only. Lift lever not availablefor air service

Detail Specification

| Sizes | ¾” x 1" to 1" x 1" |

| Orifices | D 0.127 in2(0.819 cm2) ;E 0.221 in2 (1.423 cm2) |

| Connections | MNPT x FNPT |

| Temperature range | -15°F to 400°F (-26°C to 204°C) |

| Set pressures | 15 to 1500 psig (1 to 103 barg) |

Crosby Pressure Relief Valve

Crosby Series 82 Direct Spring Operated PRV for Natural Gas

High performance, direct spring operated pressure relief valve for natural gas applications

Features

- Two piece body design with easily replaceable seat and seals reduces downtime and maintenance costs

- FKM soft seat provides repeatable leak-tight performance before and after each relief cycle

- Bubble tight at 90%

- Manufactured to ASME Section VIII UV for gas service

- Gas service only. Lift lever not availablefor air service

Detail Specification

| Sizes | ¾” x 1" to 1" x 1" |

| Orifices | D 0.127 in2(0.819 cm2) ;E 0.221 in2 (1.423 cm2) |

| Connections | MNPT x FNPT |

| Temperature range | -15°F to 400°F (-26°C to 204°C) |

| Set pressures | 15 to 1500 psig (1 to 103 barg) |

Crosby Pressure Relief Valve

Crosby Style JQ Pressure Relief Device

A combination pressure relief device designed with internal parts completely isolated from corrosive fluids and environments

Features

- Raised-face flange available as an option

- Inlet and outlet diaphragm seals effectively prevent the corrosion of internal working parts and the escape of fugitive emissions.

- 1½” (38 mm) model equipped with a special Chlorine Institute-approved inlet flange and metal-to-metal seat.

- Optional 1½” 300 lb ANSI raised face flange adapter and elastomer O-ring seat available for exceptional tightness.

Detail Specification

| Inlet sizes | 1½” and 4" (DN 40 and DN 100) |

Crosby Pressure Relief Valve

Crosby Style PVR Pressure/Vacuum Relief Valve

A versatile sanitary relief valve for the brewing, beverage, food processing and pharmaceutical industries.

Features

- Self-actuated operation

- Relieves excess air or gas pressure

- Relieves excess liquid pressure in the absence of air or gas blanketing

- Designed to prevent vacuum formation thatcould cause the vessel to buckle

- Standard FKM O-ring seats on both discs provide tight shutoff

- All materials are corrosion resistant and alexposed surface finishes are contro

Detail Specification

| Sizes | 3" and 4" (DN 80 and DN 100) |

| Inlet connections | Lug union nut, ANSI flanged, Tri-clamp |

| Set pressures | 14.5 to 125 psig (1 to 8.62 barg) |

| 2" wc (5 mbarg) | |

| Temperature range | -15 to +400°F (-26 to +204°C) |

Crosby Pressure Relief Valve

Crosby Style PVR Pressure/Vacuum Relief Valve

A versatile sanitary relief valve for the brewing, beverage, food processing and pharmaceutical industries.

Features

- Self-actuated operation

- Relieves excess air or gas pressure

- Relieves excess liquid pressure in the absence of air or gas blanketing

- Designed to prevent vacuum formation thatcould cause the vessel to buckle

- Standard FKM O-ring seats on both discs provide tight shutoff

- All materials are corrosion resistant and alexposed surface finishes are contro

Detail Specification

| Sizes | 3" and 4" (DN 80 and DN 100) |

| Inlet connections | Lug union nut, ANSI flanged, Tri-clamp |

| Set pressures | 14.5 to 125 psig (1 to 8.62 barg) |

| 2" wc (5 mbarg) | |

| Temperature range | -15 to +400°F (-26 to +204°C) |

Crosby Safety Relief Valve

Crosby Style JCE Safety

Relief Valve

Crosby Style JCE Safety Relief Valves provide full overpressure protection for process systems at an affordable cost of ownership.

Features

- Stoomwezen rules A1301.

- UDT Poland.

- Chinese SQL.

- Australian standard AS1271.

- Full lift maximum discharge capability.

- Each valve individually tested and set.

- Comprehensive range of accessories.

- Precision lapped stainless steel trim.

- Positive re-seating with either resilient or stainless steel trim.

Detail Specification

| Certified | BS6759 parts 1, 2 and 3 by SAFED. |

| Low stress springs | BS6759 |

| Australian standard | AS1271 |

Crosby Pressure Relief Valve

Crosby JB and JPVA Large Orifice Pressure Relief Valve

A large orifice pressure relief valve engineered to provide high quality, dependable overpressure protection for air, gas, vapor and steam applications

Features

- Ten size product range is the broadest

- Replaces multiple smaller valves to reduce installation and labor costs

- Fewer discharge lines

- Fewer inlet connections

- Reduced maintenance costs

- Fatigue-resistant bellows material

- Manufactured to ASME Boiler and Pressure Vessel Code, Section VIII

Detail Specification

| Sizes | 10" x 14" to 20" x 24" (DN 250 x 350 to DN 500 x 600) |

| Orifices | 47.85 to 213.82 in2 (308.71 to 1379.48 cm2 |

| Inlet rating | ANSI Class 300 |

| Temperature range | -20 to +450°F (-29 to +232°C) |

| Set Pressure | 25 to 300 psig (1.72 to 21 barg) |

Crosby Pressure Relief Valve

Crosby JB and JPVA Large Orifice Pressure Relief Valve

A large orifice pressure relief valve engineered to provide high quality, dependable overpressure protection for air, gas, vapor and steam applications

Features

- Ten size product range is the broadest

- Replaces multiple smaller valves to reduce installation and labor costs

- Fewer discharge lines

- Fewer inlet connections

- Reduced maintenance costs

- Fatigue-resistant bellows material

- Manufactured to ASME Boiler and Pressure Vessel Code, Section VIII

Detail Specification

| Sizes | 10" x 14" to 20" x 24" (DN 250 x 350 to DN 500 x 600) |

| Orifices | 47.85 to 213.82 in2 (308.71 to 1379.48 cm2 |

| Inlet rating | ANSI Class 300 |

| Temperature range | -20 to +450°F (-29 to +232°C) |

| Set Pressure | 25 to 300 psig (1.72 to 21 barg) |