Armstrong Steam Trap & Strainer

Armstrong Steam Trap

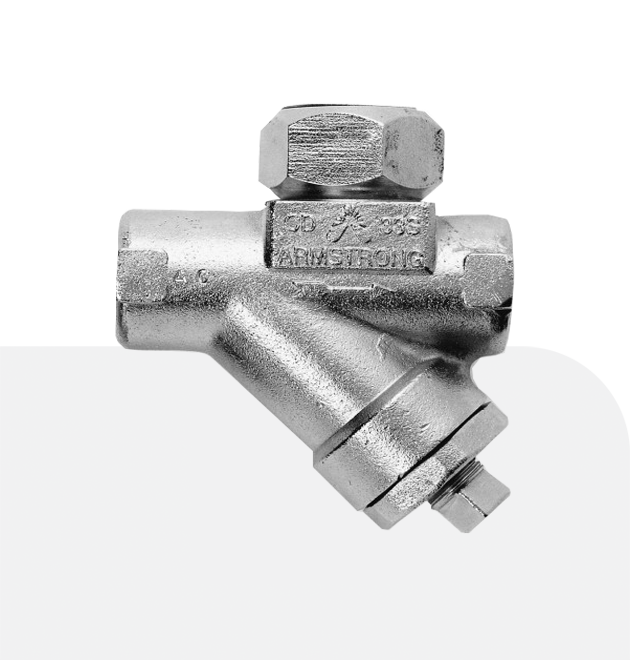

Disc Steam Traps

The Armstrong Controlled Disc (CD) Steam Trap is a time-delayed device that operates on the velocity principle.

Armstrong Steam Trap Features :

- The complete discharge

- Simplicity and small size

- Velocity of flow increases

- The system is up to temperature

- Intermittent operation for a steady

Armstrong Steam Trap Series :

Detail Specification

| Body | Dual certified Forged Corten Steel |

| Cap | ASTM A 105N / A350 LF2 Cl. 1 |

| Disc & Seat | ASTM A 564 TYP630, H900 |

| Blowdown Plug | ASTM A350 Gr. LF2 CL.1 |

Armstrong Steam Trap

Steam Trapping And System Tracing Equipment

A titanium valve and seat on high-pressure bimetallic traps ensure extremely long service life in the harsh environment of superheated steam systems, for more about the Armstrong SH/AB Series Bimetallic Steam Trap.

Armstrong Steam Trap Features :

- Seat on high-pressure

- Dependability

- Stacked nickel-chrome

- Resistance to water hammer

Armstrong Steam Trap Series :

Detail Specification

| Body and cap | ASTM A351 Gr. CF8M |

| Valve and seat | Titanium |

| Elements | Ni-Cr and stainless steel |

| Strainer | Stainless steel screen |

Armstrong Steam Trap

Steam Trapping And System Tracing Equipment

A titanium valve and seat on high-pressure bimetallic traps ensure extremely long service life in the harsh environment of superheated steam systems, for more about the Armstrong SH/AB Series Bimetallic Steam Trap.

Armstrong Steam Trap Features :

- Seat on high-pressure

- Stacked nickel-chrome

- Resistance to water hammer

Armstrong Steam Trap Series :

Detail Specification

| Body and cap | ASTM A351 Gr. CF8M |

| Valve and seat | Titanium |

| Elements | Ni-Cr and stainless steel |

| Strainer | Stainless steel screen |

Armstrong Steam Trap

Float & Thermostatic

Armstrong float and thermostatic traps are unique in their super heavy duty construction. Armstrong uses high quality ASTM A48 Class 30 cast iron or ASTM A216 WCB cast steel-normally found in pressure vessels rated to 250 psi (17 bar) or 465 psi (32 bar).

Armstrong Steam Trap Features :

- Dependability

- Long life to trapping

- High air venting capacity

- F&Ts brings Armstrong performance

- F&Ts are your most energy-efficient choice

Armstrong Steam Trap Series :

Detail Specification

| Body and cap | ASTM A48 Class 30 |

| Internals | All stainless steel—304 |

| Thermostatic air vent | Stainless steel and bronze with phosphor bronze bellows, caged in stainless steel |

| Connections | Screwed NPT and BSPT |

Armstrong Steam Trap

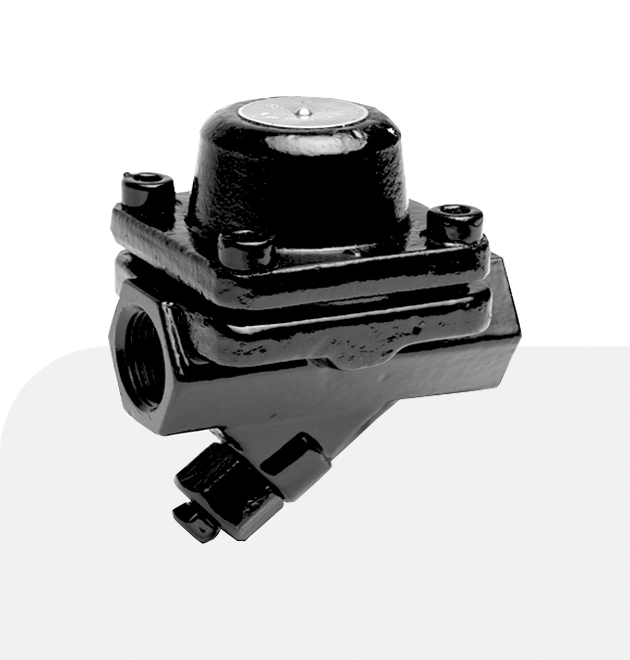

Armstrong Inverted Bucket Steam Traps

The hearts of its simple design is a unique leverage system that multiplies the force provided by the bucket to open the valve against

Armstrong Steam Trap Features :

- Venting of Air and CO2

- Corrosion Resistent Parts

- Freedom From Dirt Problems

- Operation Agaist Back Pressure

Armstrong Steam Trap Series :

Detail Specification

| Body and cap | ASTM A48 Class 30 |

| Internals | All stainless steel—304 |

| Strainer | Stainless steel |

| Connections | Screwed NPT and BSPT |

Armstrong Steam Trap

Armstrong Inverted Bucket Steam Traps

The heart of its simple design is a unique leverage system that multiplies the force provided by the bucket to open the valve against.

Armstrong Steam Trap Features :

- Venting of Air and CO2

- Corrosion Resistent Parts

- Freedom From Dirt Problems

- Operation Agaist Back Pressure

Armstrong Steam Trap Series :

Detail Specification

| Body and cap | ASTM A48 Class 30 |

| Internals | All stainless steel—304 |

| Strainer | Stainless steel |

| Connections | Screwed NPT and BSPT |

Armstrong Steam Trap

TC Series Clean Steam Thermostatic Steam Traps

Armstrong Trap Features :

- Compact and lightweight

- Highly polished for cleanability

- Easy to disassemble for cleaning

- Constructed of 316L stainless steel for corrosion resistance

Armstrong Trap Typical :

- Fermentors

- Process piping

- Sterilizers/autoclaves

- Equipment sterilization

Detail Specification

| Cap and body | ASTM A479 316L |

| Bellows | 316L Stainless Steel |

| Body gasket | Viton® |

| Clamp | Stainless Steel |

| Screws | Stainless Steel |

Armstrong Steam Trap

Radiator Traps

Armstrong is a leading supplier of radiator traps, the TS-2 has a balanced pressure thermostatic element with a high-quality multiple-convolution bellows, it’s ideal for draining.

Armstrong Trap Features :

- Heavy duty

- Unit heaters

- With a strong

- Design is well

- Repairable in-line

- Small heat exchangers

- Ideal for draining equipment

- Wafer-type trap for the drainage

- All-stainless steel wafer element

- Balanced Pressure Thermostatic

Armstrong Trap Series :

Detail Specification

| Body & Cap | Bronze, ASTM B-62 |

| Valve | Stainless Steel, Brass |

| Pipe Connections | 1/2" ~ 25" |

| Valve Seat | Stainless steel |

Armstrong Steam Trap

Radiator Traps

Armstrong is a leading supplier of radiator traps, the TS-2 has a balanced pressure thermostatic element with a high-quality multiple-convolution bellows, it’s ideal for draining.

Armstrong Trap Features :

- Heavy duty

- Unit heaters

- With a strong

- Design is well

- Repairable in-line

- Small heat exchangers

- Ideal for draining equipment

- Wafer-type trap for the drainage

- All-stainless steel wafer element

- Balanced Pressure Thermostatic

Armstrong Trap Series :

Detail Specification

| Body & Cap | Bronze, ASTM B-62 |

| Valve | Stainless Steel, Brass |

| Pipe Connections | 1/2" ~ 25" |

| Valve Seat | Stainless steel |

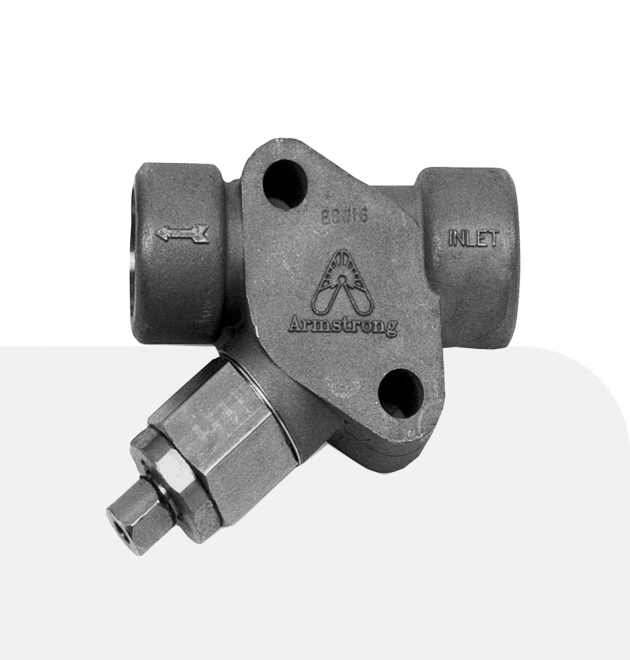

Armstrong Steam Trap

Steam Trap Connectors

Besides 2000 Series stainless steel inverted bucket traps, the standard 360° connector or IS-2 connector with integral strainer can also be used on many Armstrong thermostatic, disc, bimetallic, and float and thermostatic traps, any manufacturer’s two-bolt steam traps can use Armstrong connectors.

Armstrong Trap Features :

- A compact design

- Dependability

- Simplifying piping

- Reducing inventory

- Optional blowdown valve

- Reduces installation time

- Float and thermostatic traps

- Easy strainer screen replacement

- Applied to Armstrong’s S-2 connector

Detail Specification

| Maximum Operating | 830 psig (57.2 barg) @ 800°F (427°C) |

| Connection Types | Screwed NPT and BSPT,Socketweld,Flanged (consult factory) |

| Connector Body | All stainless steel—304 |

| End | Threaded or Socket Weld |

Armstrong Strainers

Y-TYPE STRAINER

Precise machining of both ends of the chambers is the reason. It provides perfectly round and smooth seating surfaces, as well as fixed chamber length.

Armstrong Strainer Features :

- Easy-in

- No Leak

- No Particle Large

- Easy Screwed Retainers

- No Crash Screen Chambers

Armstrong Strainer Series :

Detail Specification

| Size Range | 1/2" - 3" |

| Maximum Pressure | 400 Psig |

| Body | ASTM A48 Class 30 Cast Iron |

| Connections | ANSI B1.20.1 Screwed |

Armstrong Strainers

Y-TYPE STRAINER

Precise machining of both ends of the chambers is the reason. It provides perfectly round and smooth seating surfaces, as well as fixed chamber length.

Armstrong Strainer Features :

- Easy-in

- No Leak

- No Particle Large

- Easy Screwed Retainers

- No Crash Screen Chambers

Armstrong Strainer Series :

Detail Specification

| Size Range | 1/2" - 3" |

| Maximum Pressure | 400 Psig |

| Body | ASTM A48 Class 30 Cast Iron |

| Connections | ANSI B1.20.1 Screwed |

Armstrong Strainers

T-Type Strainer

The proven thin-wall all-stainless steel construction of Armstrong’s T-Type Strainers gives you high resistance to corrosion and freeze damage in a lightweight body designed to provide larger open screen area.

Armstrong Strainer Features :

- Easy cleaning

- Easy accessible

- Easy replacement

- Corrosive environments

- Simplifies maintenance

- Lightweight body designed

- High resistance to corrosion

- Freeze damage in a lightweight

Armstrong Strainer Series :

- T-Type Stainless Steel Strainer

Detail Specification

| Pipe Connection | 1/2" - 3/4" |

| Maximum Pressure | 400 Psig |

| Body | T304L Stainless Steel |

| Screen Retainer Wire | T316 Stainless Steel |