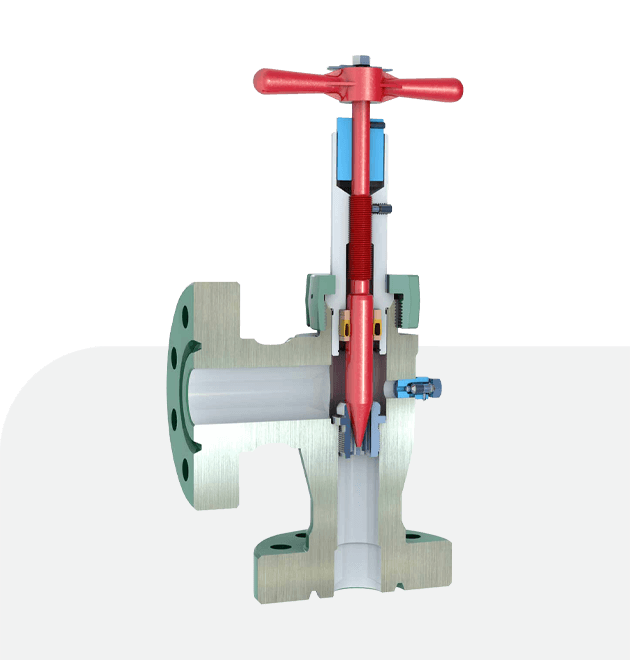

Choke Valve

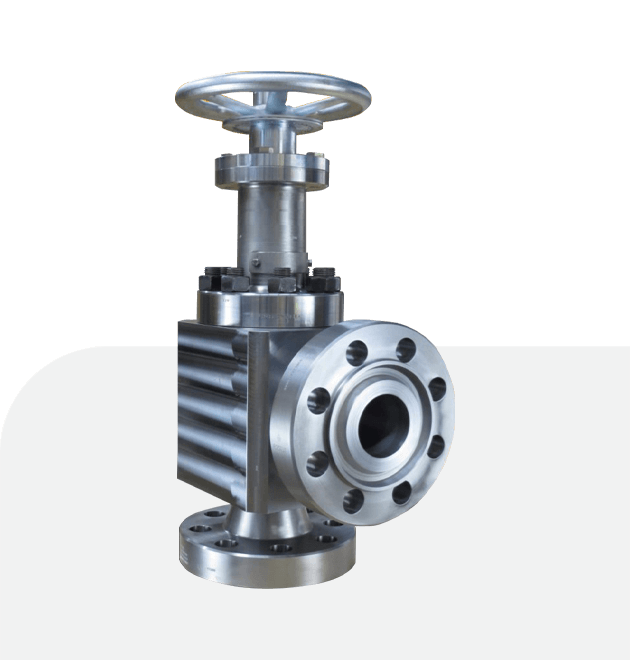

Choke Valve – External Sleeve

Choke External Sleeve

Control Valve

The external sleeve control choke has a sleeve that throttles the flow on the external diameter of the ported cage. The external sleeve trim is particularly suited for low-capacity/high pressure-drop applications. The external sleeve is designed specifically for severely erosive service where the combination of high pressure drops and high sand concentrations can reduce the life of a choke.

Features

- Available in various sizes ranging from CC15 to CC80 choke models.

- Heavy-duty thrust bearings reduce operating torque.

- Reverse angle external sleeve improves flow dynamics within the trim.

Detail Specification

| Nominal Bore | 2-1/16"~4-1/16" |

| Working Pressure | 2000psi ~ 15000 psi |

| Basic Design | API 6A |

| Test & Inspection | API 6A |

Plug And Cage Choke Valve

Plug And Cage Control

Choke Valve

The plug and cage control choke uses the plug as the controlling element and throttles the flow on the internal diameter of the ported cage. The ports in the cage are sized and arranged to give the most appropriate combination of control and flow capacity for each application.

Features

- Bleed plug assembly vents pressure before disassembly

- Antirotation key translates rotation from the drive bushing into linear movement of the lower stem/flow plug assembly

- Two-piece stem is threaded and locked and is removed from wellbore fluids

Detail Specification

| Designed and Tested | API 6A |

| End Connection | API 6A or ANSI B16.5 flanged, threaded, butt weld |

| Working Pressure | API 6A: 2000psi through 15000si. ANSI B16.5: 300lb through 2500lb |

| Performance Requirement Level | API 6A PR1, PR2 |

| Production Specification Level | API 6A PSL1, PSL2, PSL3 |

| Temperature Range | API rating K, L, P, R, S, T, U, X |

Plug And Cage Choke Valve

Plug And Cage Control

Choke Valve

The plug and cage control choke uses the plug as the controlling element and throttles the flow on the internal diameter of the ported cage. The ports in the cage are sized and arranged to give the most appropriate combination of control and flow capacity for each application.

Features

- Bleed plug assembly vents pressure before disassembly

- Antirotation key translates rotation from the drive bushing into linear movement of the lower stem/flow plug assembly

- Two-piece stem is threaded and locked and is removed from wellbore fluids

Detail Specification

| Designed and Tested | API 6A |

| End Connection | API 6A or ANSI B16.5 flanged, threaded, butt weld |

| Working Pressure | API 6A: 2000psi through 15000si. ANSI B16.5: 300lb through 2500lb |

| Performance Requirement Level | API 6A PR1, PR2 |

| Production Specification Level | API 6A PSL1, PSL2, PSL3 |

| Temperature Range | API rating K, L, P, R, S, T, U, X |

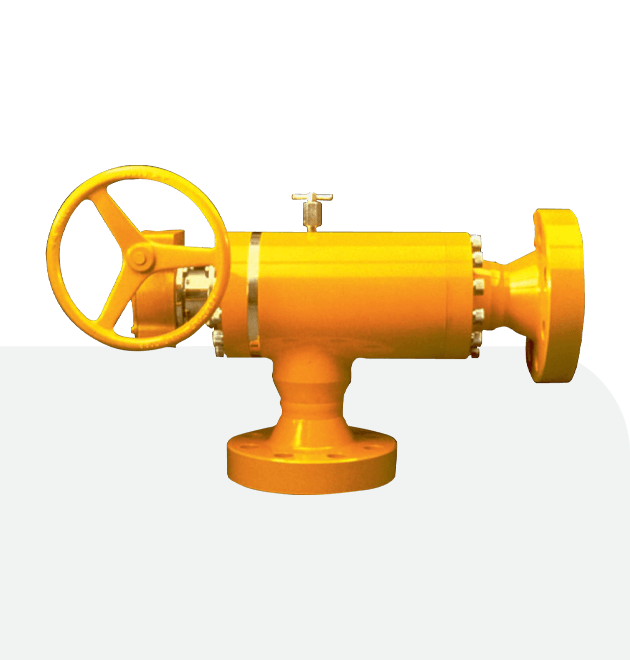

Choke Adjustable Valve

Well Control Operations To Reduce The Pressure of A Fluid

Adjustable Choke Valve has forged steel valve body, which is characterized as high pressure resistance and erosion resistance. It can be operated manually. The structure is simple and maintenance is low. It is equipped with serialized and standard choke aperture.

Features

- Externally threaded body

- Automatic venting of body pressure when you unscrews the bonnet nut one turn

- Bleed valve allows safely venting the body cavity pressure before removing the bonnet assembly

Detail Specification

| Nominal Bore | 2-1/16"~4-1/16" |

| Working Pressure | 2000psi~15000 psi |

| Temperature Level | (–60° C ~ +121° C) |

| Body Material | AA、BB、CC、DD、EE、FF、HH |

| Specification Level | PSL1~PSL3G |

| Performance Level | PR1~PR2 |

Choke Valve – Needle and Seat

Needle And Seat Choke Valve

With pressure ratings to 15,000 psi, Cameron H2 needle-and-seat chokes handle standard, erosive, and corrosive service. Once the desired flow rate is reached, the choke can be operated as a positive choke.

Features

- Externally threaded body

- Automatic venting of body pressure when you unscrews the bonnet nut one turn

- Bleed valve allows safely venting the body cavity pressure before removing the bonnet assembly

- Compliance with API Spec 6A, including performance verification testing for PR-2 chokes

- Forged body

- Easy operation and maintenance

Detail Specification

| Nominal Sizes | 2 IN, 3 IN, 4 IN |

| Pressure Range | 2000-10.000Psi, 15.000Psi, 2000-10.000Psi, 2000-5000Psi |

| Max Orifice Sizes | 1 IN, 1 IN, 2 IN, 3 IN |

| Material Class | AA, CC, DD, FF, HH |

| Body | Alloy Steel, Stainless Steel, Alloy Steel, Stainless Steel, Corrosion Resistant Alloy |

Choke Valve – Needle and Seat

Needle And Seat Choke Valve

With pressure ratings to 15,000 psi, Cameron H2 needle-and-seat chokes handle standard, erosive, and corrosive service. Once the desired flow rate is reached, the choke can be operated as a positive choke.

Features

- Externally threaded body

- Automatic venting of body pressure when you unscrews the bonnet nut one turn

- Bleed valve allows safely venting the body cavity pressure before removing the bonnet assembly

- Compliance with API Spec 6A, including performance verification testing for PR-2 chokes

- Forged body

- Easy operation and maintenance

Detail Specification

| Nominal Sizes | 2 IN, 3 IN, 4 IN |

| Pressure Range | 2000-10.000Psi, 15.000Psi, 2000-10.000Psi, 2000-5000Psi |

| Max Orifice Sizes | 1 IN, 1 IN, 2 IN, 3 IN |

| Material Class | AA, CC, DD, FF, HH |

| Body | Alloy Steel, Stainless Steel, Alloy Steel, Stainless Steel, Corrosion Resistant Alloy |

Multiple Orifice Choke Valve

Low Cost, Compact Design,

For Use with SAV Angle

Seat Valve

Orifice choke valve adopts a rotating fork, generally speaking, orifice choke valve only need 90° or 180° rotating direction, in this way, switch can be regulated. Rotating fork possesses lock position at both ends, which greatly improve the stiffness of rotating fork and make it move stably, and in this way.

Applications

- Wellhead

- Manifold

- Separator Letdown

- Heater Bypass

- Waterflood

- CO2

- Gas Lift

Detail Specification

| Sizes | 1 to 6 in [25 to 152 mm] |

| Pressure rating | 10,000 psi |

| Temperature range | –50 to 650 degF [–46 to 343 degC] |

| Compliance | API, ANSI, and NACE standards |

| End connections | Range of options |

Surface Choke Valve

Technically Advanced Surface Choke Valve

Surface choke valve offers a unique solution for the majority of choke applications in the oil and gas industry. The flexible valve design can incorporate many different trim and body material options to suit differing flow rates and in-service conditions.

Features

- Choke body materials can be of forged, HIPped or cast construction

- Robust cartridge trim (bi-directional flow option)

- Patented plug/seat design for heavily contaminated flows

- Solid or balanced plug available

Detail Specification

| Sizes | 1” to 16” (25mm to 400mm) |

| Ratings | ASME 600-4500; API 6A 3,000 - 15,000 |

| Designed and manufactured | ASME B16.34/API 6A/ISO 10423 |

Surface Choke Valve

Technically Advanced Surface Choke Valve

Surface choke valve offers a unique solution for the majority of choke applications in the oil and gas industry. The flexible valve design can incorporate many different trim and body material options to suit differing flow rates and in-service conditions.

Features

- Choke body materials can be of forged, HIPped or cast construction

- Robust cartridge trim (bi-directional flow option)

- Patented plug/seat design for heavily contaminated flows

- Solid or balanced plug available

Detail Specification

| Sizes | 1” to 16” (25mm to 400mm) |

| Ratings | ASME 600-4500; API 6A 3,000 - 15,000 |

| Designed and manufactured | ASME B16.34/API 6A/ISO 10423 |

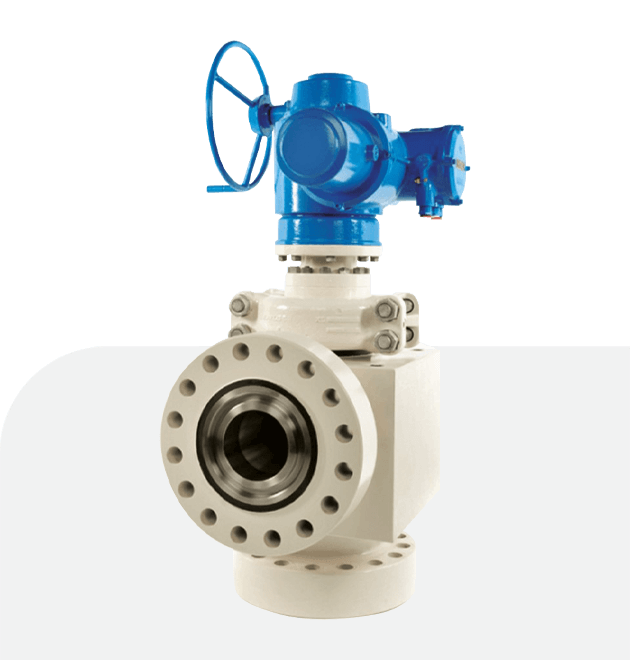

Subsea Choke Valve

Subsea Choke Valve

And Actuation

Subsea choke valves are suitable for applications including single or multi-phase production, water/chemical/gas injection and artificial gas lift.

Our versatile subsea chokes can operate in a wide range of conditions including HPHT (high pressure, high temperature).

Subsea Chokes Are Typically

- Start up and shut in subsea wells

- Balance pressures from different wells to a common manifold

- Reduce flowline pressures and costs

- Protect against reservoir collapse during startup

Detail Specification

| Choke pressure | 15,000 psi |

| Water depths | 9,800 ft [3,000 m] |

| Hydraulic operating pressure | Water- or oil-based |

| Position feedback | LVDT analog (4 to 20 mA); digital CANbus |

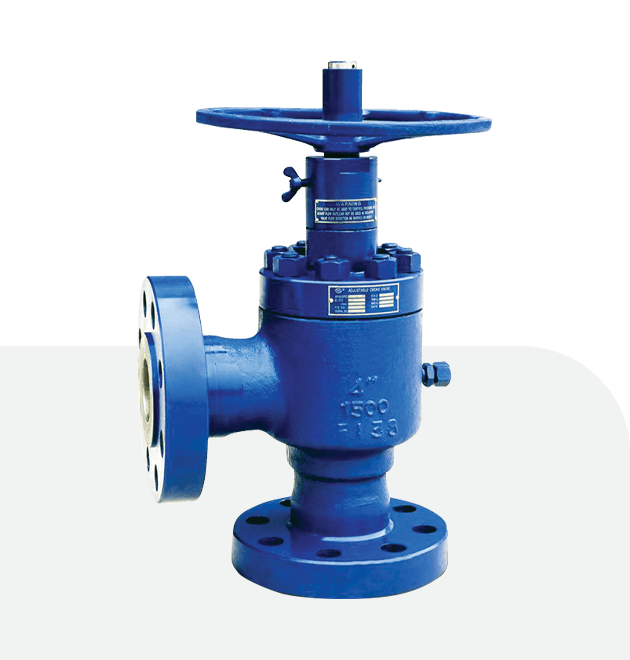

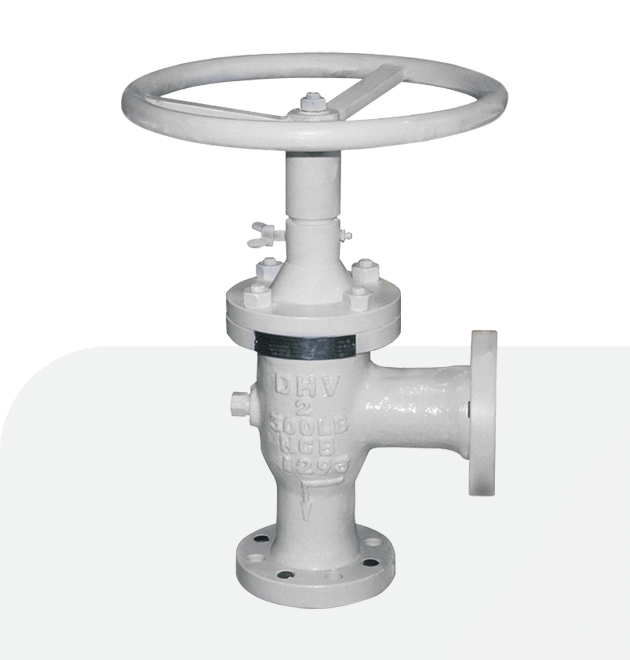

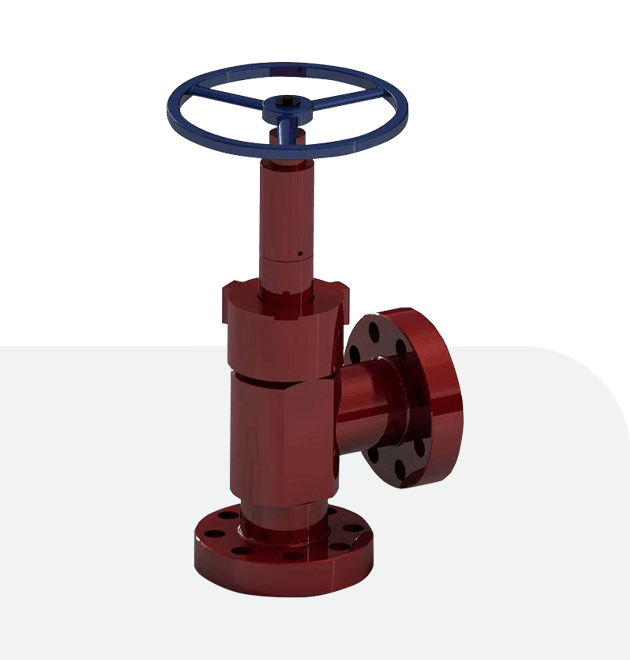

Angle Choke Valve

Angle Choke Control Valve

Our choke valve range is produced to meet the requirements of one of the following design standards, either API 6A/ISO 10423/ASME B16.34 but fundamentally the designs of valves offer the following advantages over externally guided or disc style choke valves.

Typical Industry Applications

- Oil Production Start-Up/ Shut-Down

- Gas & Condensate Production

- Choke & Kill Manifolds

- Multi-Phase Flows

- Pump Discharge

- Fracturing Clean-up

- Flaring

- Gas Lift

Detail Specification

| Sizes | 1 inch to 16 inches |

| Rating | ANSI 150# to 4500# , API 3000# to 15,000# |

| Actuators Type | Electric, Pneumatic Linear. Pneumatic Stepping, Hydraulic Linear, Hydraulic Stepping 90 Degree Angled Pneumatic or Hydraulic |

| Material | EE, FF, BB, DD, HH |

| Trim Design | External Sleeve Plug and Cage Multi-Stage, Hybrid Cage Hi-Flow Well Start-up Cage Sand Trim |

| Characteristic | Modified Equal Percent, Linear, Bi-Linear |

| Quality | API 6A PSL Level 1 to 4, PR 2, Q1 Monogramed PED CE, Independent Design Review, IVB, GOSH |

Angle Choke Valve

Angle Choke Control Valve

Our choke valve range is produced to meet the requirements of one of the following design standards, either API 6A/ISO 10423/ASME B16.34 but fundamentally the designs of valves offer the following advantages over externally guided or disc style choke valves.

Typical Industry Applications

- Oil Production Start-Up/ Shut-Down

- Gas & Condensate Production

- Choke & Kill Manifolds

- Multi-Phase Flows

- Pump Discharge

- Fracturing Clean-up

- Flaring

- Gas Lift

Detail Specification

| Sizes | 1 inch to 16 inches |

| Rating | ANSI 150# to 4500# , API 3000# to 15,000# |

| Actuators Type | Electric, Pneumatic Linear. Pneumatic Stepping, Hydraulic Linear, Hydraulic Stepping 90 Degree Angled Pneumatic or Hydraulic |

| Material | EE, FF, BB, DD, HH |

| Trim Design | External Sleeve Plug and Cage Multi-Stage, Hybrid Cage Hi-Flow Well Start-up Cage Sand Trim |

| Characteristic | Modified Equal Percent, Linear, Bi-Linear |

| Quality | API 6A PSL Level 1 to 4, PR 2, Q1 Monogramed PED CE, Independent Design Review, IVB, GOSH |

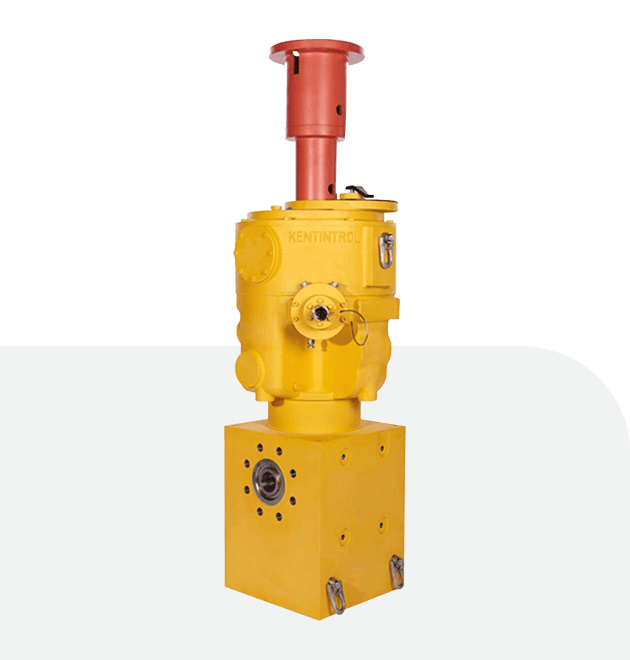

Electric Actuator Choke Valve

SVC Electric Choke Valve Actuator / Operator

SVC is a high performance linear integrated electric choke valve actuator that meets the rigorous needs of the oil and gas industry. The SVC provides a more reliable, high-speed, precision electric choke operator in performance drilling applications vs. conventional hydraulics or jack screw assemblies.

Features

- Worry-free performance in the most hazardous location environments

- Planetary roller screw for long life and no maintenance

- Fully integrated motor/actuator/feedback in a single, sealed housing

- Rugged NACE MR0175 compliant steel body

Detail Specification

| Service | Compatible gases and liquids |

| Line Size | 1/8 to 2" NPT |

| Operating Pressure | > 1/8 to 1/4": 0 psi (0 bar) to 87 psi (6 bar); 3/8 to 2": 7.3 psi (0.5 bar) to 116 psi (8 bar) |

| Pressure Limits | 174 psi (12 bar) |

| Temperature Limits | > Process: 176°F (80°C); Ambient: 32 to 149°F (0 to 65°C) |

| Power Requirements | Standard: 110 VAC; Optional: 220 VAC, 24 VDC consult factory. See Series SRC Solenoid Coils |