Check Valve

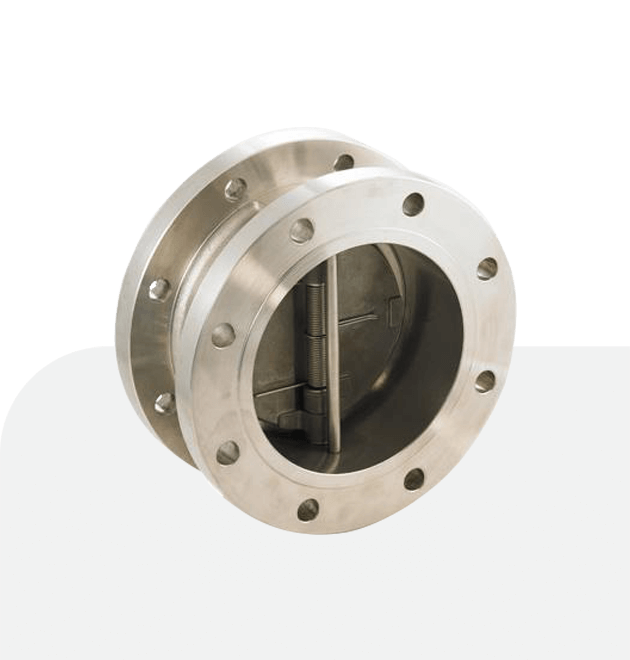

Crown Wafer Check Valve

Wafer Check Valve

Wafer check valve use a swinging disc to allow or block flow. Their design allows them to be fitted in extremely tight spaces – where the flanged check valve can not be used. The wafer check valves have molded bodies around the area where the disc opens up. Suitable for horizontal or vertical flow-up service

Wafer Check Valve Rating :

- Wafer Check Valve Class 150

- Wafer Check Valve Class 300

- Wafer Check Valve Class 400

- Wafer Check Valve Class 600

- Wafer Check Valve Class 900

- Wafer Check Valve Class 1500

- Wafer Check Valve Class 2500

Detail Specification

| Sizes | 2" - 42" |

| Pressure Rating | Class 150 to 2500 |

| Pressure Rating | ANSI Class 150 up to 600 |

| Material | Forged Steel, Stainless Steel, Exotic materials available upon request |

| Temperature | -45°C to 204°C/-50°F to 400°F |

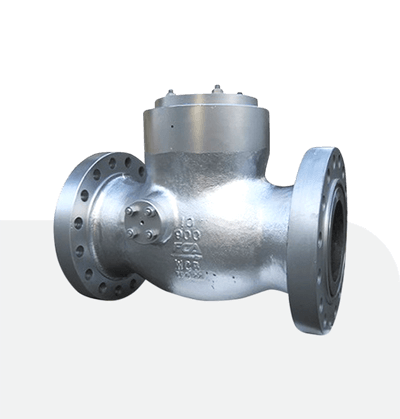

RS Model Bolted Bonnet Design Swing Check Valve

Swing Check Valve

A swing check valve has typically a globe style valve body with a hinged valve disc, to block reverse flow. The valve seat is typically full-ported in an angled our straight thru.

Check Valve Features :

- Bolted cover

- Horizontal or vertical lines

- Cast steel swing check valve

Check Valve Rating :

- Swing Check Valve Class 150

- Swing Check Valve Class 300

- Swing Check Valve Class 600

- Swing Check Valve Class 900

Detail Specification

| Connection / Flanged | JIS5K, JIS10K, DIN, ANSI |

| Size | 1/2" - 8" |

| Body Material | HI-PVC, PP, PVDF |

| Seal Material / Seat | EPDM, FKM, PTFE |

| Design Standard | DIN3352 |

| Testing Standard | ISO5208 |

RS Model Bolted Bonnet Design Swing Check Valve

Swing Check Valve

A swing check valve has typically a globe style valve body with a hinged valve disc, to block reverse flow. The valve seat is typically full-ported in an angled our straight thru.

Check Valve Features :

- Bolted cover

- Cast steel swing check valve

- Horizontal or vertical lines

Check Valve Rating :

- Swing Check Valve Class 150

- Swing Check Valve Class 300

- Swing Check Valve Class 600

- Swing Check Valve Class 900

Detail Specification

| Connection / Flanged | JIS5K, JIS10K, DIN, ANSI |

| Size | 1/2" - 8" |

| Body Material | HI-PVC, PP, PVDF |

| Seal Material / Seat | EPDM, FKM, PTFE |

| Design Standard | DIN3352 |

| Testing Standard | ISO5208 |

CHECK VALVE

SWING

Check Valve with Flanged End

Piston Check Valve

Piston Check Valve are quiet operating valve that effectively prevent backflow. The “flapperless” design is gentle on the seat as the piston rises and lowers with increased and decreased flow.

Check Valve Features :

- Conventional bore

- A105 seat base material

Check Valve Rating :

- Piston Check Valve Class 150

- Piston Check Valve Class 300

- Piston Check Valve Class 600

- Piston Check Valve Class 900

- Piston Check Valve Class 1500

- Piston Check Valve Class 2500

Detail Specification

| Pressure Rating | Class 150 - 2500 |

| Sizes | 2" - 36" |

| Basic Design | API 6D |

| Face to Face | As Stated |

| Flanged End Dimensions | ANSI/ASME 16.5 |

| Butt Weld End Dimensions | ANSI/ASME B16.25 |

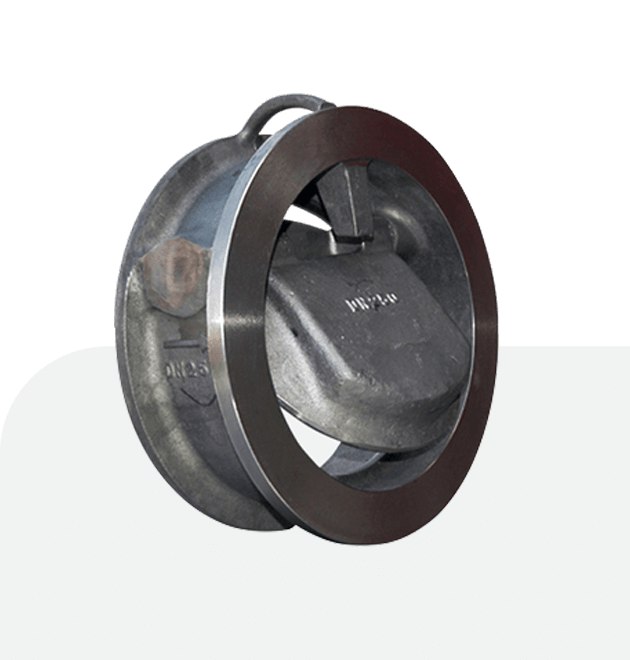

Retainerless Double Plate Check Valve | Peach

Dual Plate Check Valve

Double plate check valve are supplied retainerless as standard. Our patented design does not have any threaded plugs in the pressure boundary and totally eliminates the potential leakpath to atmosphere.

Dual Plate Check Valve Rating :

- Dual Plate Check Valve JIS 10K

- Dual Plate Check Valve JIS 20K

- Dual Plate Check Valve JIS 30K

- Dual Plate Check Valve ANSI 150#

- Dual Plate Check Valve ANSI 300#

- Dual Plate Check Valve ANSI 600#

- Dual Plate Check Valve ANSI 900#

- Dual Plate Check Valve ANSI 1500#

Detail Specification

| Size | 1 1/2”(40A) - 84”(2100A) |

| Pressure Rating | PN10 / PN16 / PN25 / PN40 |

| End Connection | Wafer, Lugged, Flanges |

| Dual Plate Check Valve Type | - Wafer Retainerless, - Flanged Retainerless, - Solid Lug Retainerless, - Hub Ended |

Retainerless Double Plate Check Valve | Peach

Dual Plate Check Valve

Double plate check valve are supplied retainerless as standard. Our patented design does not have any threaded plugs in the pressure boundary and totally eliminates the potential leakpath to atmosphere.

Dual Plate Check Valve Rating :

- Dual Plate Check Valve JIS 10K

- Dual Plate Check Valve JIS 20K

- Dual Plate Check Valve JIS 30K

- Dual Plate Check Valve ANSI 150#

- Dual Plate Check Valve ANSI 300#

- Dual Plate Check Valve ANSI 600#

- Dual Plate Check Valve ANSI 900#

- Dual Plate Check Valve ANSI 1500#

Detail Specification

| Size | 1 1/2”(40A) - 84”(2100A) |

| Pressure Rating | PN10 / PN16 / PN25 / PN40 |

| End Connection | Wafer, Lugged, Flanges |

| Dual Plate Check Valve Type | - Wafer Retainerless - Flanged Retainerless - Solid Lug Retainerless - Hub Ended |

CHECK VALVE

DUAL PLATE

RPS Model Pressure Seal Design Swing Check Valve

Pressure Seal Check Valve

Pressure Seal Check Valve are ideal for high pressure steam, liquid, catalytic reformers, hydrocrackers and other tough services. Pressure Seal Check Valve continue to provide a wide range of industries with a safe, leak free.

Check Valve Features :

- Face to face according to API 6D

- Double flange end connection

Check Valve Rating :

- Pressure Seal Check Valve Class 600

- Pressure Seal Check Valve Class 900

- Pressure Seal Check Valve Class 1500

- Pressure Seal Check Valve Class 2500

Detail Specification

| Design Standard | ASME B16.34 / BS 1868 |

| Sizes | 2” – 24” (DN50 – DN600) |

| Pressure/Temperature Chart | ASME B16.34 |

| Face to face Dimension | ASME B16.10 |

| ASME Class | 150-1500 |

| Testing Details | EN 12266-1 / API 598 |

RT Model Tilting Disc

Check Valve

Tilting Disc Check Valve

The Tilted Disc Check Valve is an excellent choice for raw water, cooling water and treated water/wastewater applications. Its streamlined body contouring, flow area 40% greater than nominal pipe size and hydrodynamic disc combine to provide the lowest headloss.

Product Overview :

- Available in Sizes 3″ – 60″

- High Performance Capabilities

Check Valve Rating :

- Tilting Disc Check Valve ANSI Class 125

- Tilting Disc Check Valve ANSI Class 150

- Tilting Disc Check Valve ANSI Class 250

Detail Specification

| Pressure Ratings | PN 10 - PN 40 |

| Sizes | DN 150 - DN 2000 |

| Connection | - With Flanges to DIN, - With flanges to international standards |

| Working Temperatures | - 12ºC up to + 130ºC for liquids, - 12ºC up to + 130ºC for gases |

| Seals | NBR, EPDM or Viton |

RT Model Tilting Disc

Check Valve

Tilting Disc Check Valve

The Tilted Disc Check Valve is an excellent choice for raw water, cooling water and treated water/wastewater applications. Its streamlined body contouring, flow area 40% greater than nominal pipe size and hydrodynamic disc combine to provide the lowest headloss.

Product Overview :

- Available in Sizes 3″ – 60″

- High Performance Capabilities

Check Valve Rating :

- Tilting Disc Check Valve ANSI Class 125

- Tilting Disc Check Valve ANSI Class 150

- Tilting Disc Check Valve ANSI Class 250

Detail Specification

| Design Standard | DIN |

| Pressure | PN10 / PN16 / PN25 / PN40 |

| Sizes | DN50/2'' to DN600/24'' |

| Sectors | - Mineral - Pulp and Paper - Steel Industry - Water |

| Material | Body : ASTM A216 WCB / ASTM A351 CF8M... Disc : ASTM A216 WCB / ASTM A351 CF8M / ASTM 890 Gr4A... |

| Seat | Metal/Metal |

| Applications | Drinking Water, Waste Water |

CHECK VALVE

TILTING DISC

Flange Ball Check Valve

Ball Check Valve

A ball check valve functions by means of a ball that moves up and down inside the valve. The seat is machined to fit the ball, and the chamber is conically shaped to guide the ball into the seat to seal and stop a reverse flow.

Ball Check Valve Features :

- Low head loss

- Medium: Water, Sewage, etc

- Installation: horizontal or vertical

- Working pressure: 1.0MPa/1.6Mpa

- Face to face accord with: DIN3202 F6

- Minimum Opening pressure: 0.002MPa

- Full bore flow, large flow, small resistance

- Pressure test according to standards: API598 | DIN3230 | EN12266-1

Detail Specification

| Flange Accord With | EN1092-2 | PN10/16 |

| Size Range | DN40 - DN400 |

| Working Temperature | NBR: 0℃~+80℃ |

| Working Temperature | EPDM: -10℃~+120℃ |

| Testing | DIN3230, API598 |

| Medium | Fresh Water, Sea water, food stuff, all kinds of oil, acid, alkaline liquid etc |