What is Gate Valve ?

Gate Valve is a type of valve that has round or rectangular-closing gate inside functioned for start or stop the fluid flow by raised or lowered the gate. A gate valve is the most common type of valve used in any process plant.

Gate Valve Installation and Application

Gate valve installation with the principle is quite simple, by using 2 threaded connectors or using 2 flanges connected to the pipe.

Gate valve are designed for fully open or fully closed operation. They are installed in pipelines as isolating valve, and should not be used as control or regulating valve. The operation of a gate valve

is either turning the handle clockwise to

close or to open.

Gate valve are used with almost all fluid such as air, fuel gas, feedwater, steam, lube oil, hydrocarbon. Some special gate valve are used in slurry and powder products too, such as knife gate valve.

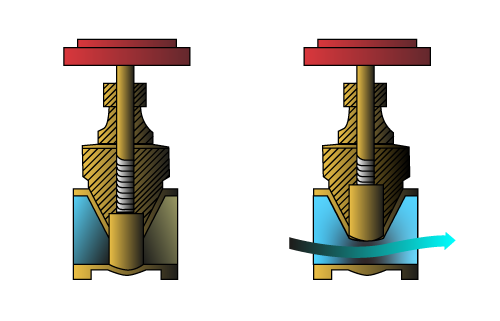

The Working Principle of Gate Valve

When the handle is turned, it caused bonnet raised to the connector with a change stopping wedge area forcing the movement to be up and down. The handles that raise and lower the stopper take up bonnet area. The stopper goes into the chamber where the liquid is passing through.

In the open or close position, this type of valve can be identified by the height and the low of the handle. If the handle position is low it means the valve is opened, and if the position is high it means the valve is closed.

The valve casing that is slightly wider than the connected pipes allows the stopper to cover the flow chamber and make it completely closed.

Gate Valve Function

The main functioned of this valve is to shut and open the flow entirely. Gate Valve is not designed for regulation and throttling by opening the gate half-way, quarter-way, or part of its position, apart from being inaccurate that activity will trigger turbulence which caused :

- Erosion in the gate angles

The turbulence fluid flow rate can scrape the gate angles which later caused erosion that leads to valve working imperfectly. - Changes in the gate seat position

The closing gate will swing towards the seat position, so that over time its position will change to the seat so that if the valve closes, the closing gate will not be in the right position, causing

a passing.

Advantages of Gate Valve

- Low pressure drop while fully opened

- Excellent and very stable while fully closed

- Contamination-free

- There is no pressure when gate fully closed. Easy to fix or repair needed in the pipe

- High flow capacity

- Low cost

- Incomplex design and operation

- Flow friction against the valve is minimal

Disadvantages of Gate Valve

- It cannot be used to regulate or throttle the flow

- Not suitable to use half-opened

- It takes longer time to open or close the valve and require high torque

- Not suitable to apply in steam for size 10” above

- Hard to control the flow because when the flow still flowing it must be stopped suddenly

- Need higher power from gate

- Opening and closing drive position continuously can cause erosion